FACILITY EXPANSION

- 9000 Square Foot Expansion

- Upgraded Welding Ventilation System

- Addition of 2 Extra Welding Beds

- Automated Welding Cell

- Automated Bending Cell

- Automated Laser Cutter Tower

- Relocation of 4 Welding Beds w/ Overhead Crane

- Increased Storage Capacity

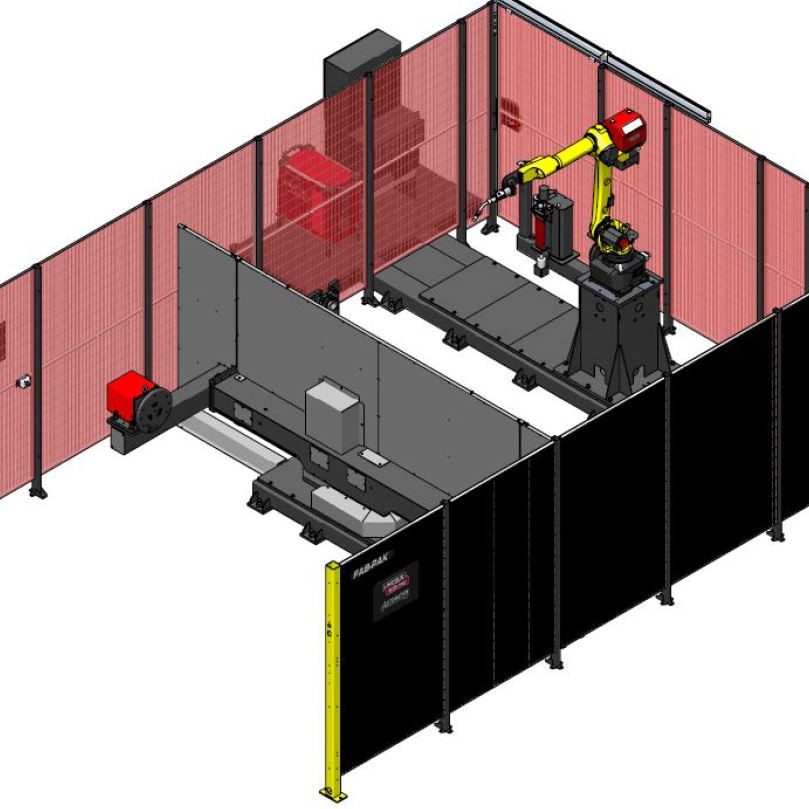

Robotic Welding

Lincoln Electric FAB-PAK XHS-CM

6-axis Fanuc Robotic Welding Arm

Rotating parts carrier enables simultaneous welding, loading and unloading of hot and cold assemblies

Increased weld quality

Significantly increased weld speed

Robotic Bending

Trumpf TruBend Cell 5000 BendMaster 150 ToolMaster

Automatic tool changing

Robotic Arm on a 16m track

Laser guided angle detection

Capable of lifting parts up to 220 lbs

Up to 120"x60" flat part size

260 tons of press force

Laser guided bending detection ensures absolute bend accuracy regardless of variances in material composition or thickness

Robotic arm can lift the largest parts up to 220 lbs 120"x60" eliminating the need for cranes and multiple operators

Vastly increased bending speeds

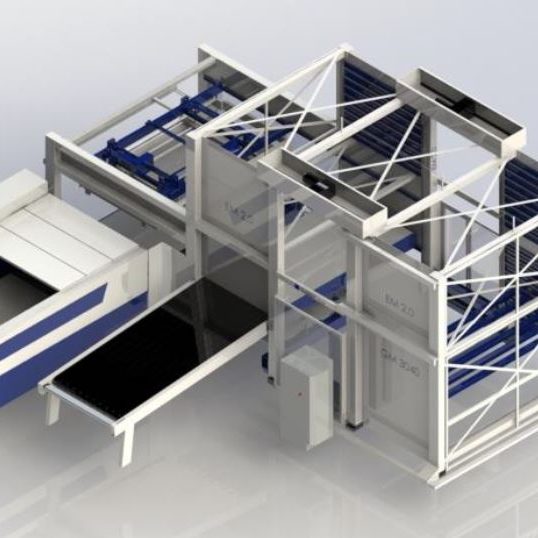

3040 Laser Upgrades

TruStore3000 PartMaster LiftMaster Compact

6000w fibre optic laser

Automated sheet storage tower

Automated material loading and unloading

Conveyor based parts removal

Lights out automated cutting

260,000 lbs capacity

Conveyor fed unloading reduces physical labour and health/safety risks associated with heavy lifting and use of crane equipment

Greatly reduced material handling. Raw material stored directly in the machine

No forklift and suction crane required to feed the machine

Fully automated overnight cutting. No night shift required. Overnight cut parts are palletized and scrap removed the following morning shift

Eliminates operator errors such as: cutting too many sheets, incorrect material type, and cutting wrong job